TAG:

Six Sigma

Six Sigma, like Lean, is used to improve the quality and efficiency of operational processes. During the past decade, these process improvement techniques increasingly have been applied outside of the manufacturing sector, for example, in healthcare.

While Lean focuses on identifying ways to streamline processes and reduce waste, Six Sigma aims predominantly to make processes, such as those used in clinical laboratories and pathology group labs, more uniform and precise through the application of statistical methods.

Along with Lean, this process improvement technique has become popular with labs as a way to streamline laboratory processes, reduce costs, increase productivity, and improve quality in a time when labs are increasingly pressured by downward price trends for lab tests. At the same time, labs are able to increase value offered to “customers,” that is, patients.

The principles of a Six Sigma-based system were originally developed by Bill Smith of Motorola in 1986 as a way of eliminating defects in manufacturing, where a defect is understood to be a product or process that fails to meet customers’ expectations and requirements. The name refers to a quality level defined as the near-perfect defect rate of 3.4 defects per million opportunities. As a process improvement strategy, it gained much attention through its association with General Electric and its former CEO Jack Welsh.

Six Sigma also involves the training and certification of designated process specialists (called black belts, green belts, or other similar titles) within organizations to help guide Six Sigma improvement efforts. Other distinctive features include the expectation that process quality improvements be translated into financial metrics to assess value and the active involvement of top management in all initiatives.

Six Sigma is often combined with Lean management techniques to produce a methodology that relies on a collaborative team effort to improve performance by systematically removing waste (Lean) as well as defects, overproduction, waiting, non-utilized talent, transportation, inventory, motion and extra-processing (Six Sigma).

To Add Value, Focus on Patient Care

By R. Lewis Dark | From the Volume XXIV No. 15 – October 30, 2017 Issue

FOR THE PAST SEVERAL YEARS, and particularly since Congress passed the Patient Access to Medicare Act in 2014, clinical labs have focused on controlling costs, as they should. After all, PAMA calls …

August 7, 2017 Intelligence: Late Breaking Lab News

By Robert Michel | From the Volume XXIV No. 11 – August 7, 2017 Issue

PAML of Spokane, Washington, was the subject of an unusual public disclosure recently made by Laboratory Corporation of America. The lab company sent a statement to the Spokane Journal of Business stating its plans to make PAML “its primary lab site in the western…

New Business Models for Pathology, Clinical Labs

By R. Lewis Dark | From the Volume XXIV No. 7 – May 15, 2017 Issue

EXPERTS OFTEN PROCLAIM THAT THE U.S. HEALTHCARE SYSTEM is slow to change and slow to adopt the management approaches, operational innovations, and new technologies that other industries use. One example is adoption of the quality management techniques that W. Edwards Deming and the Japanese develope…

ARUP Laboratories Earns CAP’s ISO 15189 Accreditation

By Joseph Burns | From the Volume XXIV No. 5 – April 3, 2017 Issue

CEO SUMMARY: Being accredited to this internationally recognized standard for quality and competence communicates to clients and prospective clients that one of the nation’s largest clinical labs is committed to the highest standards of quality. Clients already knew about that commitmen…

Marshfield Clinic Lab Tackles Phlebotomy Workflow Redesign

By Joseph Burns | From the Volume XXIII No. 5 – April 11, 2016 Issue

CEO SUMMARY: Before a redesign of phlebotomy workflow at Marshfield Clinic, patients might wait as long as an hour, particularly before noon when phlebotomists would see 75% of each day’s patients. After the redesign, the number of draw sites was reduced from five to two while hand…

Henry Ford Health System Labs Show How Lean Methodology in Healthcare Increases Revenues

By Mary Van Doren | From the Volume XXIII No. 3 – February 29, 2016 Issue

EXECUTIVE SUMMARY: Here’s a major accomplishment by the lab division of a nationally-recognized health system that has gone unreported until this DARK REPORT intelligence briefing. This article explains how using the quality management system of ISO 15189 and the Lean methodology in …

Henry Ford Health System Laboratory Division Combines Lean with ISO 15189

By Joseph Burns | From the Volume XXIII No. 3 – February 29, 2016 Issue

CEO SUMMARY: As healthcare transitions away from fee-for-service payment and adopts new models of reimbursement, every clinical lab will need to deliver more value with its lab testing services. At Henry Ford Health System in Detroit, the laboratory division has blazed a path of improving…

Top laboratory management requires top business skills

By Mary Van Doren | From the Volume XXII No. 5 – March 30, 2015 Issue

Every lab organization should aspire to achieve the attributes of Level Four: Use Benchmarks to Achieve Best-in-Class because this is the level of performance where the lab is delivering optimal clinical value at highest quality and lowest cost. This is an effort in which the business skills…

Benchmarking with the Best To Be a World Class Laboratory

By Robert Michel | From the Volume XXII No. 5 – March 30, 2015 Issue

CEO SUMMARY: This fourth installment of this special series about the laboratory value pyramid introduces “Level Four: Use Benchmarks to Achieve Best-in-Class.” This is the highest level of the four level pyramid. When a lab organization performs at this level, it will be deliver…

Gearing Up the Laboratory to Exceed Expectations of External Customers

By Robert Michel | From the Volume XXII No. 3 – February 17, 2015 Issue

CEO SUMMARY: This is the third installment of THE DARK REPORT’S description of the Laboratory Value Pyramid. It describes “Level Three: Deliver Value that Exceeds Expectations.” This is the level where the laboratory organization now shifts its emphasis from internal operation of…

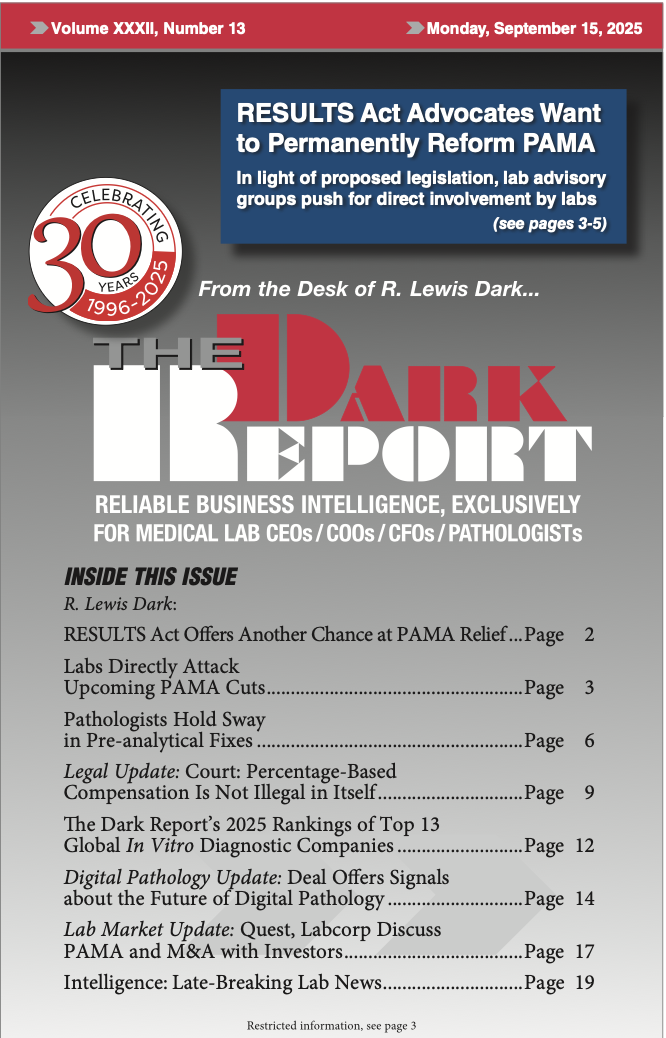

CURRENT ISSUE

Volume XXXII, No. 13 – September 15, 2025

The Dark Report examines a new bill that would reform PAMA and avoid reimbursement rate cuts scheduled for January 2026. Clinical laboratory leaders are urged to make their voices heard in Congress. Also, an expert describes how labs can fix pre-analytical errors and avoid disaster.

See the full table of contentsHow Much Laboratory Business Intelligence Have You Missed?

Lab leaders rely on THE DARK REPORT for actionable intelligence on important developments in the business of laboratory testing. Maximize the money you make-and the money you keep! Best of all, it is released every three weeks!

Sign up for TDR Insider

Join the Dark Intelligence Group FREE and get TDR Insider FREE!

Never miss a single update on the issues that matter to you and your business.

Topics

- Anatomic Pathology

- Clinical Chemistry

- Clinical Laboratory

- Clinical Laboratory Trends

- Digital Pathology

- Genetic Testing

- In Vitro Diagnostics

- IVD/Lab Informatics

- Lab Intelligence

- Lab Marketplace

- Lab Risk & Compliance

- Laboratory Automation

- Laboratory Billing

- Laboratory Compliance

- Laboratory Equipment

- Laboratory Information Systems

- Laboratory Management

- Lean Six Sigma

- Managed Care Contracts

- Molecular Diagnostics

- Pathology Trends

- People

- Uncategorized