CEO SUMMARY: In this unusual collaboration, the participating Pennsylvania hospitals dramatically reduced blood specimen labeling errors. This initiative to share best practices incorporated techniques that were refined in other projects designed to reduce medical errors and improve patient care. Another interesting feature of this multi-hospital quality initiative is that the participating institutions agreed to publish …

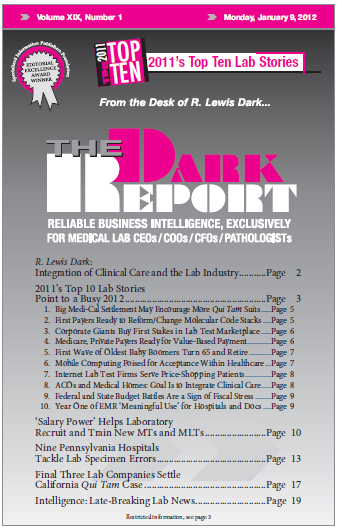

9 Pennsylvania Hospitals Tackle Lab Specimen Errors Read More »

To access this post, you must purchase The Dark Report.