CEO SUMMARY: It’s an important milestone for the clinical laboratory profession. Quest Diagnostics Incorporated South Florida, based in Deerfield Beach, Florida, earned the 2007 Florida Governor’s Sterling Award for quality. This is only the second laboratory in this country to win a state quality award. But that’s just part of the story. Guided by the …

Quest South Florida Wins Governor’s Award for Quality Read More »

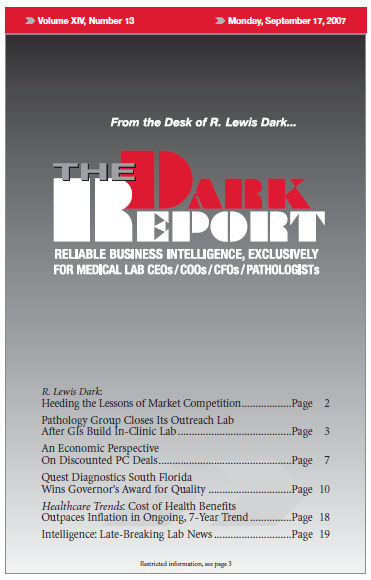

To access this post, you must purchase The Dark Report.