CEO SUMMARY: In more than 40 presentations by 55 speakers, two big themes dominated the 11th annual Lab Quality Confab in New Orleans last week. One theme is the urgent need to cut clinical laboratory costs. The second theme is the need for both clinical labs and anatomic pathology groups to deliver more value to …

Labs Begin Applying Lean to Cut Costs, Add Value Read More »

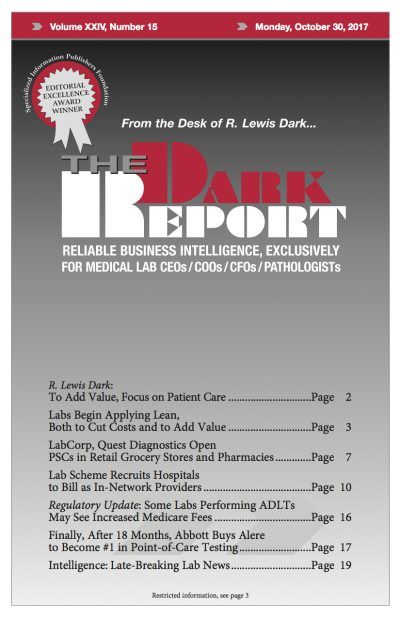

To access this post, you must purchase The Dark Report.