Lean Six Sigma

Lean Six Sigma is a management technique consisting of both Lean and Six Sigma techniques. This produces a methodology that relies on a collaborative team effort to improve performance by systematically removing waste (Lean) as well as defects, overproduction, waiting, non-utilized talent, transportation, inventory, motion and extra-processing (Six Sigma).

Lean production, often simply “Lean,” is a systematic method for the elimination of waste within a manufacturing process. Lean also takes into account waste created through overburden and waste created through unevenness in workloads. Working from the perspective of the client who consumes a product or service, “value” is any action or process that a customer would be willing to pay for.

Essentially, Lean is centered on making obvious what adds value by reducing everything else. Lean manufacturing is a management philosophy derived mostly from the Toyota Production System (TPS) and identified as “lean” only in the 1990s.

Six Sigma, like Lean, is used to improve the quality and efficiency of operational processes. During the past decade, these process improvement techniques increasingly have been applied outside of the manufacturing sector, for example, in healthcare.

While Lean focuses on identifying ways to streamline processes and reduce waste, Six Sigma aims predominantly to make processes, such as those used in clinical laboratories and pathology group labs, more uniform and precise through the application of statistical methods.

The principles were originally developed by Bill Smith of Motorola in 1986 as a way of eliminating defects in manufacturing, where a defect is understood to be a product or process that fails to meet customers’ expectations and requirements. The name refers to a quality level defined as the near-perfect defect rate of 3.4 defects per million opportunities. As a process improvement strategy, it gained much attention through its association with General Electric and its former CEO Jack Welsh.

This combined process improvement has become popular with clinical laboratories as a way to streamline laboratory processes and cut costs in a time when labs are increasingly pressured by downward price trends for lab tests. At the same time, labs are able to increase value offered to “customers,” that is, patients.

The Lean Six Sigma concepts were first published in a book titled Lean Six Sigma: Combining Six Sigma with Lean Speed by Michael George and Robert Lawrence Jr. in 2002. Training is provided through the belt based training system similar to that of Six Sigma. The belt personnel are designated as white belts, yellow belts, green belts, black belts and master black belts, similar to karate.

Allina Opens State-of-the-Art Central Laboratory Facility

By Robert Michel | From the Volume XXX, No. 12 – August 21, 2023 Issue

THIS MONTH, THE NATION’S NEWEST “designed from scratch” clinical laboratory facility began operating in Minneapolis, Minnesota. It is the central laboratory of Allina Hospitals & Clinics and its design is rooted in Lean and similar process improvement and workflow principle…

WellSpan’s Lab Designs the “Ideal” Phlebotomy

By Robert Michel | From the Volume XXX, No. 12 – August 21, 2023 Issue

CEO SUMMARY: Lengthy wait times for patients at phlebotomy sites is a common problem for labs across the country. But the laboratory at WellSpan Health System in York, Pennsylvania decided to apply Lean methods to change this situation. Their Lean projects at two pilot patient se…

Quality Strategy Earns Honor for SD Laboratory

By Robert Michel | From the Volume XXX, No. 12 – August 21, 2023 Issue

CEO SUMMARY: Here’s a new lab product launch with a surprise twist. Upon earning FDA clearance for its new HIV Ag/Ab Combo Assay this spring, Abbott Diagnostics selected a hospital laboratory in Sioux Falls, South Dakota, to be the nation’s first clinical lab to offer the ass…

Third Laboratory Earns ISO 15189 Accreditation

By Robert Michel | From the Volume XXX, No. 12 – August 21, 2023 Issue

CEO SUMMARY: In June, the laboratory at Blanchard Valley Hospital became third in the nation to be accredited to ISO 15189:2007. The 150-bed acute facility in Findlay, Ohio, is the only hospital laboratory of its size to achieve accreditation to the ISO 15189 standard. Implementi…

Using Lean to Cut Pap Test TAT Pays Off At Baystate Medical

By Robert Michel | From the Volume XXX, No. 12 – August 21, 2023 Issue

USE OF LEAN METHODS HAS UNLOCKED major improvements at Baystate Health’s Department of Pathology in Springfield, Massachusetts. One Lean project cut average Pap test turnaround time by more than 50%. Another Lean project attacked errors with Advanced Beneficiary No…

Using Lean at Henry Ford Transforms Pathology TAT

By Robert Michel | From the Volume XXX, No. 12 – August 21, 2023 Issue

CEO SUMMARY: Long-standing work flow traditions in anatomic pathology provide fertile ground for improvement with Lean and similar process improvement methods. That was the case at Henry Ford Health System, where empowered teams in the pathology laboratory employed the principles…

Boston’s Beth Israel Scores Improvement Gains with Lean

By Robert Michel | From the Volume XXX, No. 12 – August 21, 2023 Issue

CEO Summary: Lean methods are helping laboratories resolve aggravating problems that have been unresolvable for as long as 10 years. At Beth Israel Deaconess Medical Center in Boston, improvement teams involving the laboratory and ED staff addressed high rates of hemolyzed specim…

When Does Cost Cutting Affect a Lab’s Quality?

By Robert Michel | From the Volume XXX, No. 12 – August 21, 2023 Issue

CEO SUMMARY: Many lab professionals note the irony that a laboratory so publicly committed to Six Sigma quality management methods is now identified with the single largest episode of systemic failure in lab test accuracy. Looking in from the outside, some pathologists suggest th…

Cytology Lab Uses Lean to Simplify Processes

By Robert Michel | From the Volume XXX, No. 12 – August 21, 2023 Issue

CEO SUMMARY: Like many labs today, the gynecologic cytology laboratory at the University of Iowa Hospitals and Clinics had a pre- and post-analytical work flow with many complex steps. This work flow—heavily influenced by a legacy of previous information systems—was inefficient, conta…

Piedmont Med Lab Mixes ISO with Lean & Six Sigma

By Robert Michel | From the Volume XXX, No. 12 – August 21, 2023 Issue

CEO SUMMARY: Piedmont Medical Laboratory (PML) could be the only clinical laboratory ever to pursue three quality improvement initiatives simultaneously. Even as it was in the early stages of implementing both Lean and Six Sigma methods, PML also decided to seek ISO 15189:2007 accreditati…

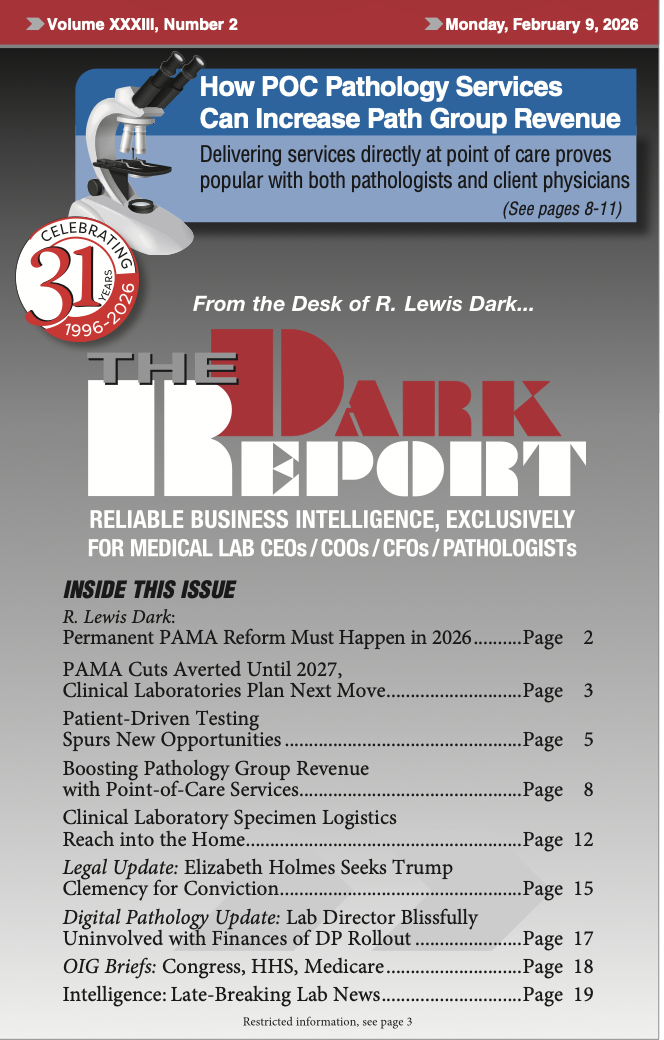

CURRENT ISSUE

Volume XXXIII, No. 2 – February 9, 2026

Congress has once again delayed cuts to test reimbursement rates under PAMA, this time until Jan. 1, 2027. Laboratory professionals are urged to lobby Congress to pass the RESULTS act to solve the PAMA cuts problem permanently. Also, patient-driven testing is spurring new opportunities.

See the full table of contentsHow Much Laboratory Business Intelligence Have You Missed?

Lab leaders rely on THE DARK REPORT for actionable intelligence on important developments in the business of laboratory testing. Maximize the money you make-and the money you keep! Best of all, it is released every three weeks!

Sign up for TDR Insider

Join the Dark Intelligence Group FREE and get TDR Insider FREE!

Never miss a single update on the issues that matter to you and your business.

Topics

- Anatomic Pathology

- Clinical Chemistry

- Clinical Laboratory

- Clinical Laboratory Trends

- Digital Pathology

- Genetic Testing

- In Vitro Diagnostics

- IVD/Lab Informatics

- Lab Intelligence

- Lab Marketplace

- Lab Risk & Compliance

- Laboratory Automation

- Laboratory Billing

- Laboratory Compliance

- Laboratory Equipment

- Laboratory Information Systems

- Laboratory Management

- Lean Six Sigma

- Managed Care Contracts

- Molecular Diagnostics

- Pathology Trends

- People

- Uncategorized