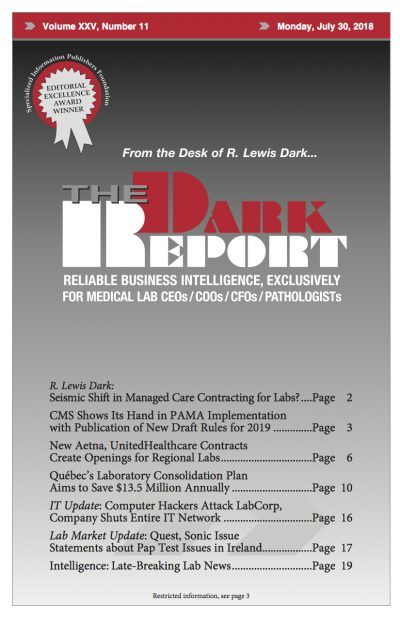

CEO SUMMARY: In the Province of Québec, an ambitious project is under-way to consolidate the clinical laboratory testing of 123 laboratories into 11 centralized lab clusters. It is one of the largest lab consolidation projects nowhappening in the world. Among the goals of this project is to improve qualityand efficiency while incurring no additional costs. …

Québec’s Laboratory Consolidation Plan Aims to Save $13.5M Read More »

To access this post, you must purchase The Dark Report.